Principle of vacuum centrifugal concentrator

A vacuum pump is used to form a vacuum in the concentrator, and the air pressure in the instrument is reduced, so that the boiling point of the solvent of the sample is reduced, and the solvent can boil and evaporate at low temperature; In addition, it can increase a certain amount of heat in the instrument cavity, thus improving the evaporation rate;

The sample will produce centrifugal force at centrifugal speed, which prevents the loss caused by dissolution and evaporation, and also avoids the phenomenon of a large amount of foam in the centrifugal tube caused by heating and centrifugation.

Application of vacuum centrifugal concentration

In electrophoresis, real-time fluorescence quantitative PCR, sequencing, mass spectrometry, gas chromatography, high performance liquid chromatography and other experiments, the demand for sample concentration is high, and high-concentration samples can be prepared by vacuum centrifugal concentration for loading, and the nucleic acid and protein samples after centrifugal concentration can be conveniently used for various qualitative and quantitative analysis.

The vacuum centrifugal concentrator will not produce problems such as cross-contamination, sample loss, sample denaturation, sample activity reduction or oxidation when preparing samples with high concentration. Therefore, the vacuum centrifugal concentrator is especially suitable for preparing sensitive biological samples, such as nucleic acid and protein.

It is suitable for the concentration and drying of DNA/RNA and protein in laboratories of molecular biology, biochemistry, genetics, analytical chemistry and quality control.

More application

Concentration of biological macromolecules such as ▪DNA, RNA, protein and enzyme.

Concentration of clinical specimens, such as blood.

Organic solvent extraction, chromatography and HPLC sample recovery.

Solution concentration of soil and seeds

Carbon ring intelligent manufacturing has a keen insight into the pain points of the existing industry, and 12 functions have been upgraded comprehensively and intelligently, and a vacuum centrifugal concentrator CV100-TH with higher sex ratio, intelligence and portability has been introduced.

Advantages of carbon ring intelligent vacuum centrifugal concentrator

Highlight 1

integrated design

Thzz-plus centrifugal main engine, the whole machine is anti-corrosive, high-quality and durable.

The vacuum pump is built-in with the host, which is compact and light, eliminating any complicated installation procedures.

Silica gel sheet is used for heating, which has large heating area, fast heating speed and even heating.

Slim body, lighter and smaller in size

Highlight 2

Accurate temperature sensing and temperature control

Built-in accurate pressure probe to master pressure data in real time.

Programmable temperature control, precise temperature control

Accurate temperature sensing probe, accurate temperature control.

Large-area silica gel sheet is used for heating, so that the heating is uniform and the temperature is more uniform.

Highlight 3

Custom vacuum function

You can customize the delayed start or close time of the vacuum pump to protect the sample from pollution.

You can customize the rotor delay start-up or shut-down time to protect the sample from pollution.

Maintenance-free non-contact drive system ensures high vacuum stability inside the instrument.

Built-in accurate pressure probe to master pressure data in real time.

Highlight 4

Programmable software

U disk upgrades the software with one button, which is simple and quick.

Open programming can define the process according to the requirements and meet the personalized needs of any experimental scene.

Software function debugging interface, which can independently control each module of drying, centrifugation and concentration.

It is convenient to use a function alone.

Highlight 5

Programmable intelligent control chip

Innovative use of PLC controller to replace the traditional circuit board of vacuum centrifugal concentrator

Microprocessor control, fully automatic operation

Precise adjustment of vacuum, speed, temperature, time, etc., more intelligent and accurate.

Highlight 6

Large-size Led touch screen

Using 7-inch LED touch screen instead of general instrument buttons makes it more convenient to display touch integration.

Real-time grasp the instrument running state such as temperature, vacuum degree, rotor speed, remaining time,

Dynamically display information such as running progress.

Program information can be edited directly.

Highlight 7

Original imported diaphragm pump

The pumping rate is more than or equal to ≥40L/min, which can reach the ninety-seven percent vacuum degree and meet the requirements of centrifugal concentration.

Teflon anticorrosive coating has better corrosion resistance.

Highlight 8

Water drop trap

Integrated water drop catcher, real-time solution collector

Highlight 9

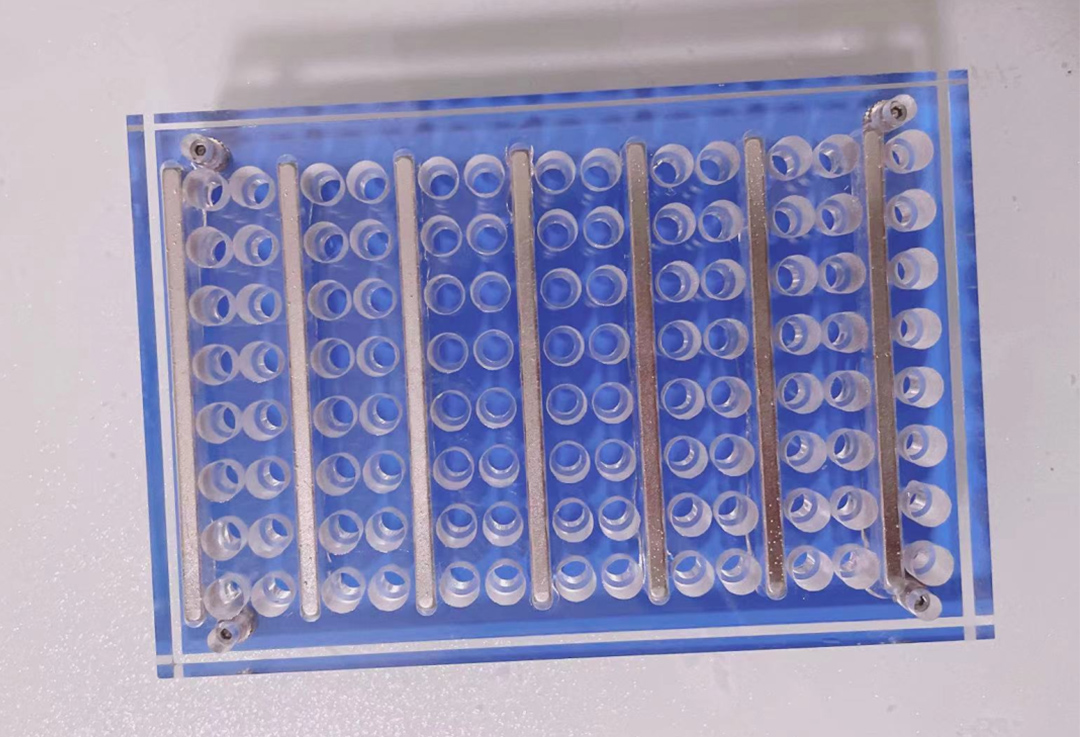

Multi-specification rotor optional

Centrifugal rotor is standard, which can handle 40 samples of 1.5 ml and 8 samples of 0.5ml at a time.

There are also a variety of specifications of the rotor can be customized to meet any of your needs.

Highlight 10

A variety of power protection measures

Short-circuit protection, overload protection, over-voltage protection, over-temperature protection, and various protection methods.

Ensure that safety of your property and life.

Highlight 11

Metal support bar

Support rod, easy to open the lid to place and take out samples.

Prevent samples from falling and losing samples, and avoid potential safety hazards.

Highlight 12

Private silence

Built-in silencer, active noise reduction and mute, maximum operating decibel ≤60 decibels.

Other characteristics

Concentration time: 0~10000min

Transparent cover, easy to observe the progress.

Keep the temperature low: avoid sample loss, denaturation, activity decline and oxidation.

Concentration effect: it sinks evenly and is easy to collect.

Prevent sample loss

No cross-contamination phenomenon

Can treat mixed solution of water and organic solvent.

It can handle high boiling point and temperature sensitive materials such as DMSO(189℃), NMP(203℃) and DMF(152.8℃).

Centrifuge Tube Magnetic Rack Series

Centrifuge Tube Magnetic Rack Series